Introduction

Last year, a mid-sized logistics company I consulted for discovered something terrifying: their entire customer database had been compromised—not through their own systems, but through a third-party shipping software vendor they’d trusted for years. The breach cost them $2.3 million and nearly destroyed their reputation overnight.

This isn’t a rare horror story. Securing your information supply chain has become one of the most pressing challenges for businesses in 2025. When you think about supply chain security, you might picture physical warehouses and shipping containers. But today’s most critical vulnerabilities exist in the digital realm—in the software, data flows, and vendor relationships that keep your business running.

In this guide, you’ll learn why information supply chain security matters, what threatens it, and practical steps to protect your organization from the inside out.

What Is Information Supply Chain Security?

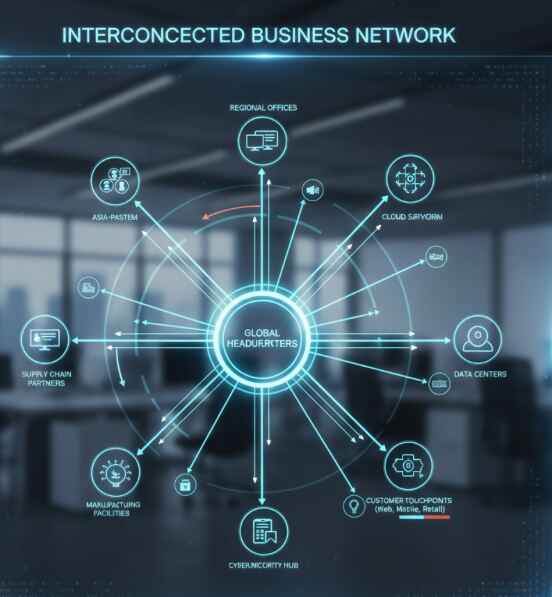

Think of your information supply chain as the entire ecosystem of data, systems, and partners that touch your business operations. It’s not just about what happens within your four walls—it’s about every vendor, contractor, software tool, and cloud service that has access to your information.

Supply chain cybersecurity focuses on protecting this complex web of connections. When you use accounting software, collaborate with manufacturers, or store data in the cloud, you’re extending your digital perimeter. Each connection is a potential entry point for cybercriminals.

The reality? You’re only as secure as your weakest vendor.

Why Your Business Can’t Ignore Supply Chain Vulnerabilities

The Rising Tide of Third-Party Risks

Here’s a sobering stat: over 60% of data breaches now involve third-party vendors. These aren’t direct attacks on your infrastructure—they’re sneaky backdoor entries through partners who may not have the same security standards you do.

Third-party risk management isn’t optional anymore. Every SaaS tool, every API integration, every contractor with system access represents a potential vulnerability. The 2020 SolarWinds attack proved this dramatically when hackers compromised software updates, affecting thousands of organizations including government agencies.

Real-World Consequences That Hit Hard

Poor supply chain security doesn’t just mean technical headaches. It translates to:

- Financial losses: Average breach costs exceed $4 million

- Reputation damage: Customer trust evaporates faster than you can issue a press release

- Regulatory penalties: GDPR, CCPA, and industry-specific regulations impose hefty fines

- Operational disruption: Business grinds to a halt during incident response

I’ve seen companies spend months rebuilding customer relationships after a single vendor-related breach. The indirect costs often dwarf the immediate financial hit.

Key Threats Lurking in Your Information Supply Chain

Software Vulnerabilities and Outdated Code

That legacy system you’re still running? The one that “works fine, so why fix it?” Yeah, that’s a ticking time bomb. Attackers love outdated software because known vulnerabilities are published and easily exploitable.

Software supply chain vulnerability mitigation requires constant vigilance. This means regular patching, monitoring security advisories, and sometimes making the tough call to replace legacy systems.

Counterfeit Components and Malicious Code

It’s not just physical goods that get counterfeited. Malicious actors insert backdoors and compromised code into legitimate-looking software components. This is where the concept of Software Bill of Materials (SBOM) becomes critical—knowing exactly what’s in your software stack, where it came from, and whether it’s trustworthy.

The Human Element: Social Engineering

No technology can fix the problem of employees clicking phishing links or vendors with weak password policies. Vendor security assessments must include evaluating partner training programs and security culture, not just technical controls.

Building a Fortress: Best Practices for Supply Chain Security

1. Implement Rigorous Vendor Vetting

Don’t wait until after you’ve signed the contract to ask about security. Your vendor security assessment process should include:

- Security questionnaires covering encryption, access controls, and incident response

- Third-party audits and certifications (SOC 2, ISO 27001)

- Regular security posture reviews

- Contractual security requirements with teeth

Pro tip: Create a tiered vendor classification system. Not every vendor needs the same scrutiny, but those handling sensitive data should face rigorous evaluation.

2. Deploy Multi-Layered Security Controls

Think of security like Swiss cheese—each slice has holes, but stack enough slices together and nothing gets through. Your defenses should include:

| Security Layer | Implementation | Purpose |

|---|---|---|

| Data Encryption | End-to-end encryption for data in transit and at rest | Protects confidentiality even if intercepted |

| Multi-Factor Authentication | Required for all vendor access points | Prevents unauthorized access via stolen credentials |

| Network Segmentation | Isolate vendor access to specific systems | Limits breach impact if compromise occurs |

| Continuous Monitoring | Real-time threat detection across supply chain | Identifies anomalies before they become breaches |

3. Embrace Emerging Technologies

AI in supply chain security isn’t science fiction anymore—it’s practical reality. Machine learning algorithms can:

- Detect unusual patterns in vendor behavior

- Predict potential vulnerabilities before exploitation

- Automate threat response at machine speed

- Analyze vast amounts of security logs humans couldn’t process

Meanwhile, blockchain supply chain security provides tamper-proof transaction records. Every handoff, every data exchange gets recorded in an immutable ledger. It’s particularly powerful for tracking physical goods and preventing counterfeit infiltration.

4. Establish Strong Incident Response Protocols

Hope for the best, plan for the worst. Your incident response supply chain plan should address:

- Who gets notified when (vendor breaches require different playbooks)

- Communication templates for customers, regulators, and partners

- Forensic investigation procedures

- Recovery priorities and backup systems

Practice these scenarios annually. Tabletop exercises reveal gaps before real incidents expose them.

5. Master Compliance and Frameworks

Supply chain compliance isn’t just about avoiding fines—though those certainly hurt. Frameworks like NIST Cybersecurity Framework, ISO 27036, and industry-specific standards provide proven blueprints for security programs.

Staying compliant also simplifies vendor management. When everyone follows the same standards, security expectations become clear and auditable.

Top Tools to Secure Your Information Supply Chain

You don’t need to build everything from scratch. Leading organizations leverage specialized platforms:

- BitSight Security Ratings provides continuous third-party risk monitoring with easy-to-understand security scorecards

- CyberGRX benchmarks vendor cyber risk against industry standards

- Darktrace Enterprise Immune System uses AI to detect supply chain threats in real-time

- OneTrust Vendor Risk Management automates assessment workflows and compliance tracking

- Venafi protects machine identities and cryptographic keys across distributed environments

These tools don’t replace human judgment, but they dramatically scale your ability to monitor hundreds or thousands of vendor relationships.

(Source: BlueVoyant Knowledge Center)

The Future: What’s Next for Supply Chain Security?

IoT supply chain monitoring is transforming physical logistics. GPS-enabled sensors, temperature monitors, and tamper-evident tags provide real-time visibility into shipments. This isn’t just about knowing where products are—it’s about detecting anomalies that indicate theft, counterfeiting, or compromise.

Quantum-resistant encryption is also emerging as a critical consideration. While quantum computers capable of breaking current encryption don’t exist yet, organizations are already preparing for that future by implementing crypto-agility—the ability to swap encryption algorithms quickly.

Conclusion: Your Move

Securing your information supply chain isn’t a one-time project—it’s an ongoing commitment. The vendors you trust today might become tomorrow’s vulnerability if their security practices slip. The software that’s secure now might contain tomorrow’s zero-day exploit.

Start with vendor assessments. Review your current third-party relationships and classify them by risk. Implement multi-factor authentication everywhere vendor access exists. Build incident response plans before you need them.

Most importantly, make supply chain security a board-level conversation. This isn’t just an IT problem—it’s a business continuity imperative.

What’s your biggest supply chain security concern? Drop a comment below or share this guide with your security team. And if you need help assessing your current risk posture, check out our [comprehensive security assessment toolkit].

(Additional resources: Risk Ledger Resources)

Frequently Asked Questions

Q: How often should we reassess vendor security posture?

A: Continuously, ideally. At minimum, conduct formal reviews annually for all vendors and quarterly for those handling sensitive data. Automated security rating platforms can provide real-time monitoring between formal assessments.

Q: What’s the difference between supply chain security and vendor risk management?

A: Vendor risk management is one component of broader supply chain security. While vendor risk focuses on third-party service providers, supply chain security encompasses the entire ecosystem including software components, hardware, logistics, and information flows throughout your operations.

Q: Do small businesses really need sophisticated supply chain security programs?

A: Absolutely. Small businesses are actually more vulnerable because they often lack dedicated security teams. The good news? You can start with basics: vendor security questionnaires, contract security requirements, and tools like BitSight that scale to smaller organizations. Focus on your highest-risk vendors first.

Q: How do we balance security requirements with vendor relationships?

A: Security shouldn’t kill partnerships—it should strengthen them. Frame security requirements as mutual protection rather than distrust. Most reputable vendors appreciate working with security-conscious partners because it reduces their risk exposure too. Build security conversations into procurement from the start rather than bolting them on later.

Q: What role does employee training play in supply chain security?

A: Huge. Employees are often the first line of defense against supply chain attacks, especially social engineering targeting vendor credentials. Regular security awareness training should include recognizing phishing attempts, proper credential management, and reporting suspicious vendor behavior.

Q: Can blockchain really prevent counterfeit products in supply chains?

A: Yes, when implemented properly. Blockchain creates immutable records of product provenance, making it nearly impossible to insert counterfeits without detection. Industries like pharmaceuticals and luxury goods are already seeing significant results. However, blockchain is a tool, not a magic bullet—it requires proper implementation and adoption across the supply chain to be effective.

(Source: GoComet Supply Chain Security Blog)